Boss fatigue fractures arise as a consequence of mechanical overstressing. The constant overstressing of the piston material increasingly results in alternating bending stresses and material fatigue. This process can be accelerated if there is no sufficient oil supply. Cause ●Abnormal combustion, in particular spontaneous combustion caused by ignition delay. ●Excessive or inappropriate use of starting aids during cold starts. ●The cylinder has filled up with water, fuel or oil whilst the engine is stopped. ●Performance enhancements with use of the standard production piston. ●Incorrect or weight-reduced piston pins. Damage assessment The cause is an exceptionally fast sequence of hard impacts as the piston crown strikes the cylinder head, which subjects the piston to such violent shock vibrations that cracks are generated. The piston also no longer runs straight in the cylinder and subsequently strikes the cylinder wall with its skirt. On pistons with a lower oil control ring the skirt often breaks in the area of the lower oil ring groove. Possible causes for the damage ●Excessive clearances in the connecting rod bearings or a worn-out connecting rod bearing, particularly in conjunction with over-revving when driving downhill. ●The minimum distance between the piston crown and the cylinder head was too small at TDC of the piston. The following scenarios may have caused this: ①Pistons with an incorrect compression height. ②Insufficient thickness of the cylinder head gasket. Many manufacturers provide cylinder head gaskets with different thicknesses for the same engine. This is necessary to compensate for component tolerances during production, and it also allows adaptation of the piston protrusion during repairs. For this reason, when carrying out repairs ensure that only cylinder head gaskets with the prescribed material thickness are used. This ensures that the specified gap dimension will be achieved after the repair.

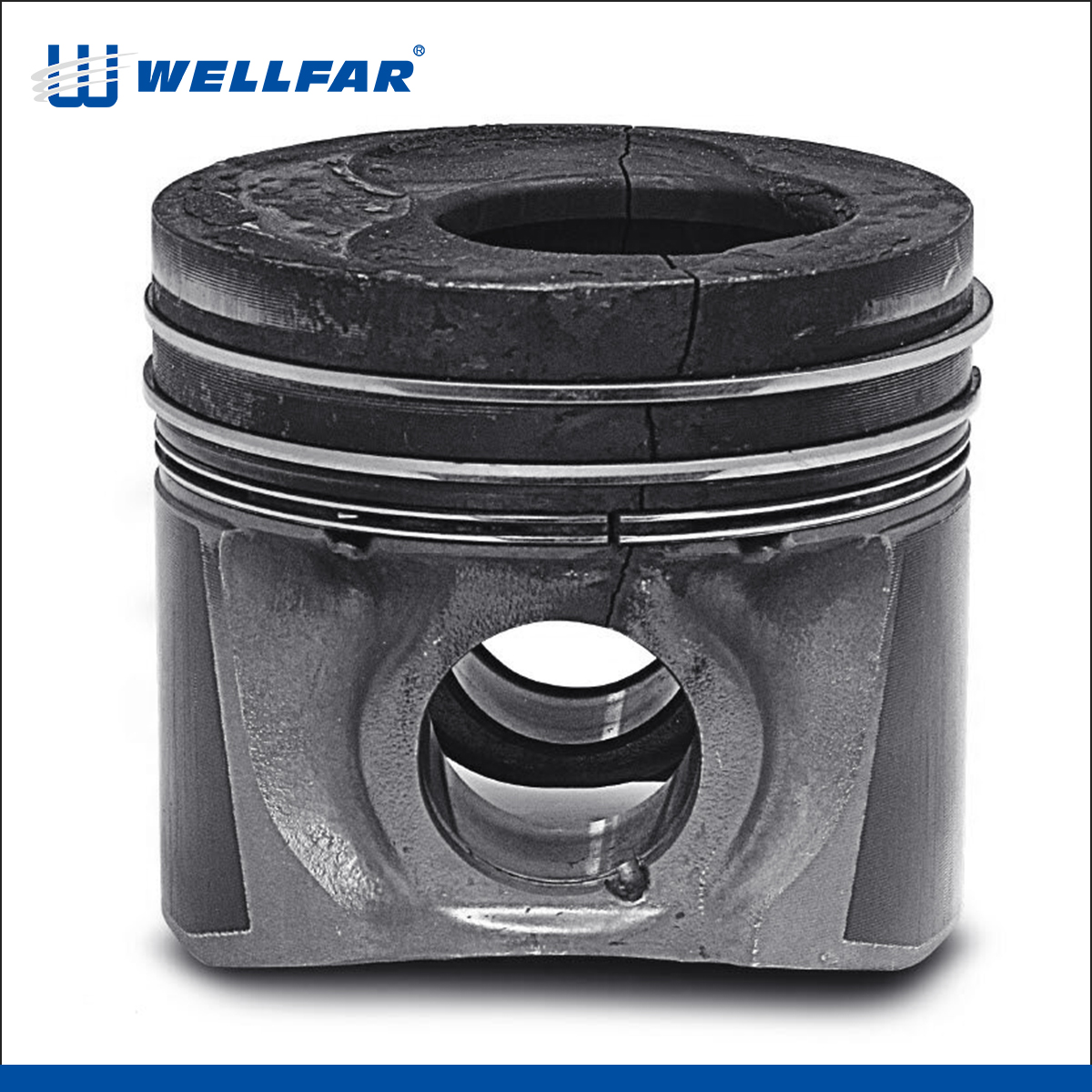

Piston Boss Fatigue Fractures

2026-01-14 01:47