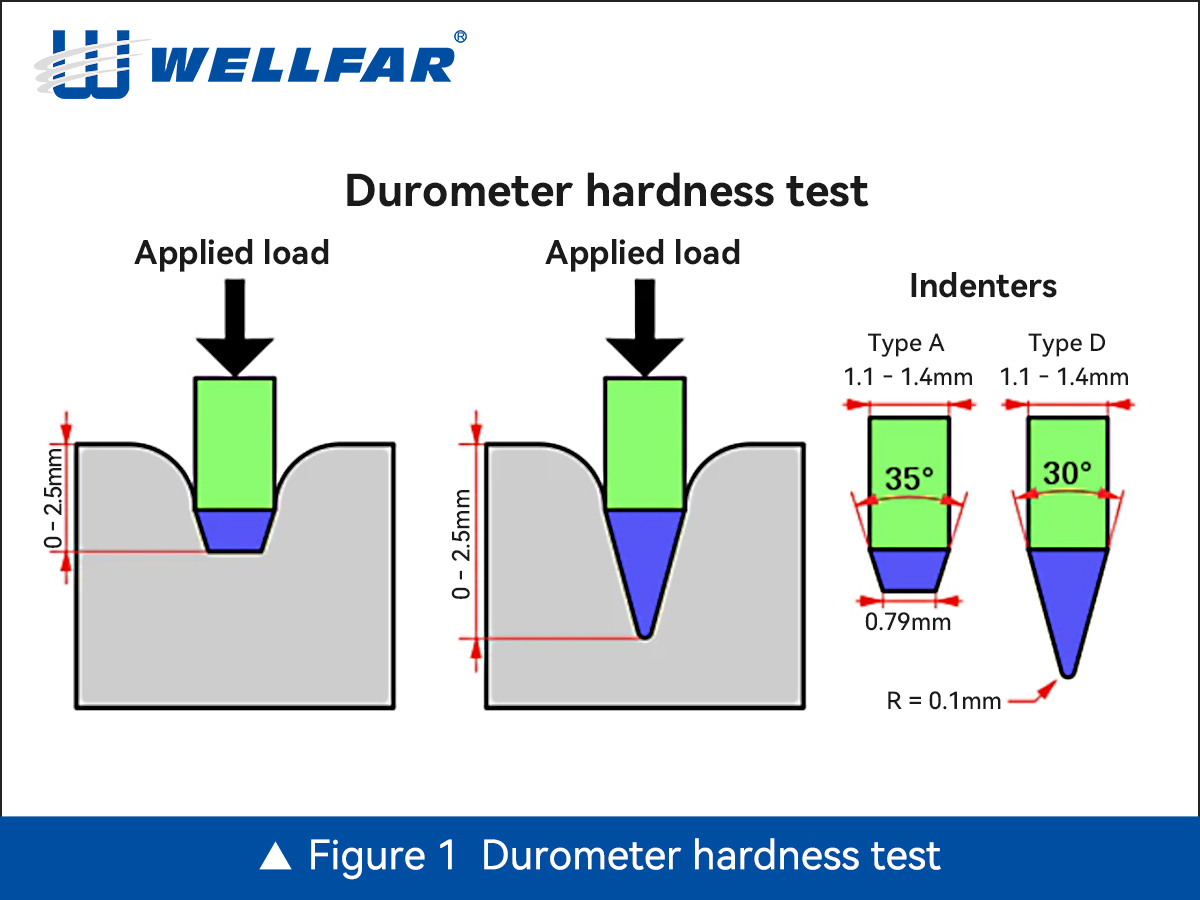

O-ring quality is defined by mechanical properties like hardness, compression set, and abrasion resistance, as well as dimensional accuracy (inside diameter and cross-section) and suitability for the application, including temperature range, chemical compatibility, and pressure conditions. Manufacturers use standards like ISO 3601-3 and inspect for defects like bubbles, cracks, and uneven surfaces to ensure the O-ring meets the necessary quality grade for critical or general applications. Mechanical properties include: Hardness: Measured in Shore A durometer as figure 1 shows. Harder O-rings offer greater abrasion and extrusion resistance, while softer ones provide better sealing on rough surfaces. Compression Set: Refers to the O-ring's ability to return to its original shape after being compressed. A lower compression set indicates better elasticity and a more reliable long-term seal, especially under changing conditions. Elasticity & Resilience: The O-ring's ability to spring back after compression is crucial for maintaining a seal, adapting to changes, and withstanding pressure peaks. Abrasion Resistance: How well the O-ring withstands wear and friction, particularly important in dynamic applications with moving parts. Material & chemical properties include: Temperature Range: Different rubber compounds (e.g., Viton, EPDM, Silicone) have varying capabilities for resisting extreme heat or cold, vital for specific applications. Chemical Compatibility: The O-ring material must be resistant to the specific fluids or gases it will encounter to prevent degradation and ensure a proper seal. Dimensional & physical attributes like: Dimensional Accuracy: The O-ring must meet precise inside diameter and cross-section specifications, often identified by a standardized dash number. Surface Quality: The O-ring's surface should be smooth, without defects such as bubbles, cracks, or impurities, which can compromise its sealing ability. Other considerations Operating Pressure: High-pressure applications require harder O-rings to resist extrusion into the gap between sealing surfaces. Type of Fluid/Gas: The chemical nature and properties of the working fluid influence the choice of elastomer for optimal resistance and longevity. Compression (Indentation): The amount the O-ring is compressed in the groove must be within recommended limits (e.g., 15-25% for static, 8-16% for dynamic) to prevent premature damage.

How To Choose O Rings

2025-12-18 01:26